- Product Details

- Technical Parameters

- Inquiry Now

- Related Products

product description

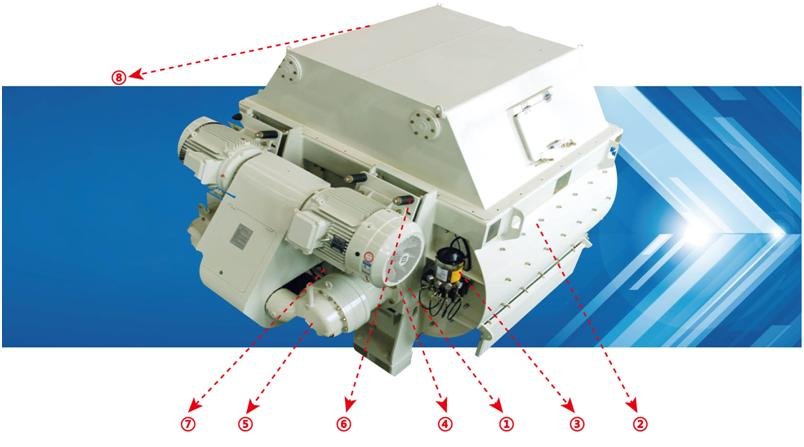

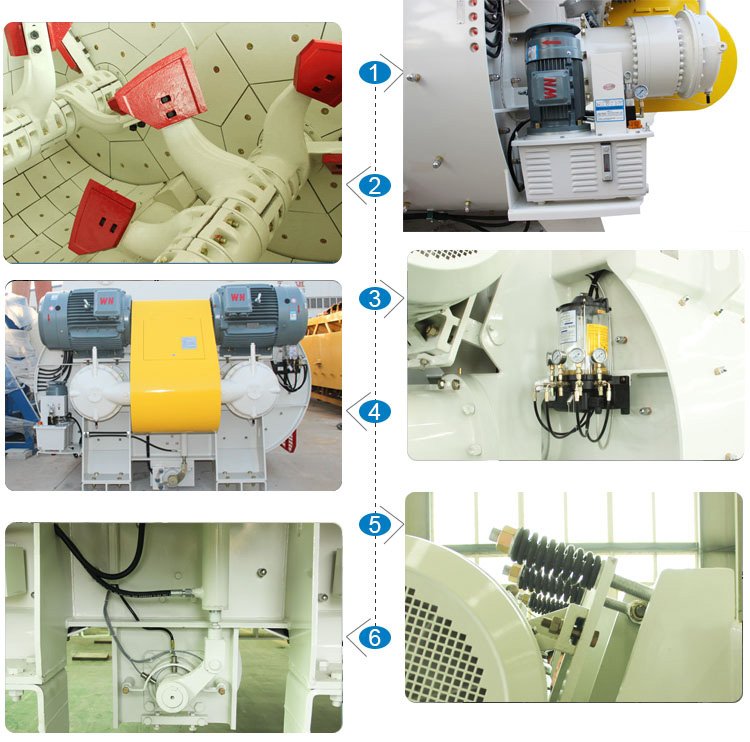

(1) Shaft sealing

The double-layer sealing structure consisting of a floating oil seal ring, a special seal and a mechanical seal is adopted, and the high-pressure grease is combined to ensure the service life and reliability of the shaft seal, and it is also easy to disassemble and replace.

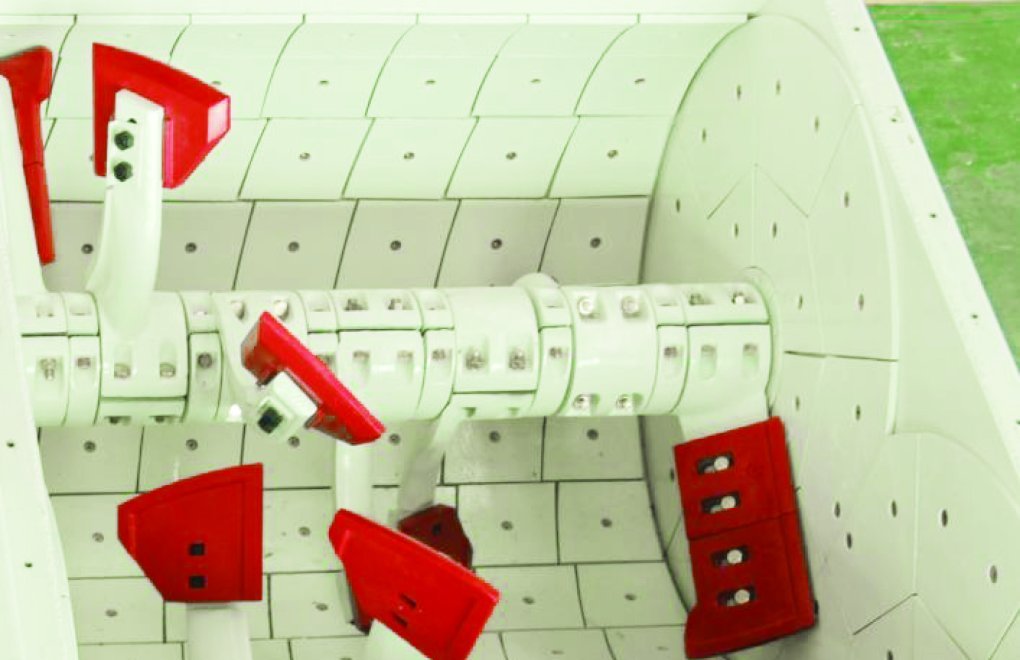

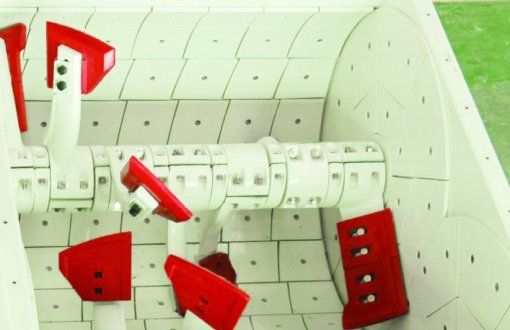

(2) Mixing device (twin-shaft forced mixer)

The streamlined mixing arm and the 60-degree angle design not only produce radial cutting effect on the material during the mixing process, but also more effectively play an axial driving role, making the material mixing more intense and reaching a homogeneous state in a short time. In addition, due to the unique design of the mixing device, the cement utilization rate is improved. At the same time, a 90-degree angle design option is provided to meet the use requirements of large-particle materials.

(3) Automatic grease lubrication

The electric lubrication pump supplies oil to the four shaft ends through four pump cores. The grease has high pressure, convenient maintenance, high viscosity and reliable sealing. At the same time, the oil consumption is small, which can effectively reduce the pollution of grease to concrete.

(4) Shaft bearing

The main shaft bearing of CO-NELE main machine is designed to be separated from the shaft end seal. When the shaft end seal is damaged, it will not affect the normal operation of the bearing. In addition, this design facilitates the removal and replacement of the shaft end seal.

(5) Drive device

The drive device adopts two planetary gear reducers for transmission. This design has a compact structure, stable transmission, low noise and long service life.

(6) Belt self-tensioning device

Installing a belt self-tensioning device in the drive device can maintain the stable output efficiency of the equipment for a long time, while avoiding abnormal wear and damage of the belt and reducing the labor intensity of maintenance personnel.

(7) Discharging device

The discharging door adopts an eccentric design and a double-layer sealing structure, which has reliable sealing and low wear. In addition, a material baffle is installed on the door body to reduce the occurrence of material accumulation.

(8) Inspection door

It adopts a large opening design, which is durable and beautiful.

Product details

| 型号Type 项目Item | CHS500 | CHS750 | CHS1000 | CHS1250 | CHS1500 | CHS2000 | CHS2500 | CHS3000 | CHS3500 | CHS4000 | CHS4500 | CHS5000 | CHS6000 | CHS8000 |

| 进料容量(L) Input capacity | 750 | 1125 | 1500 | 1875 | 2250 | 3000 | 3750 | 4500 | 5250 | 6000 | 6750 | 7500 | 9000 | 12000 |

| 出料容量(L) Output capacity | 500 | 750 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 8000 |

| 搅拌电机功率(KW) Mixer power | 18.5 | 30 | 37 | 22×2 | 30×2 | 37×2 | 45×2 | 55×2 | 55×2 | 75×2 | 75×2 | 90×2 | 55*4 | 90*4 |

| 泵站电机功率(KW) Hydraulic power | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 5.5 |

| 搅拌管个数(个) Paddles number | 2*4 | 2*4 | 2*5 | 2*5 | 2*6 | 2*6 | 2*7 | 2*8 | 2*9 | 2*9 | 2*10 | 2*11 | 2*12 | 2*12 |

| 重量(Kg Weight | 3200 | 3500 | 4700 | 5000 | 5400 | 7800 | 8300 | 8900 | 9500 | 12000 | 14000 | 16000 | 18000 | 22000 |

| 外形尺寸(mm) Dimension | 2490 1780 1700 | 2710 2190 1700 | 2780 2190 2030 | 3000 2190 2030 | 2970 2190 2030 | 3200 2620 2265 | 3440 2620 2265 | 3670 2620 2265 | 3900 2620 2265 | 4080 2950 2450 | 4360 2950 2450 | 4870 2950 2450 | 5650 2950 2450 | 6680 3340 2965 |